/

The perfect solution for light to heavy-duty applications.

Aluminum Extrusion

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

From planning and design to fabrication and installation, our team of engineering specialists help create a customized solution designed to meet your extrusion requirements.

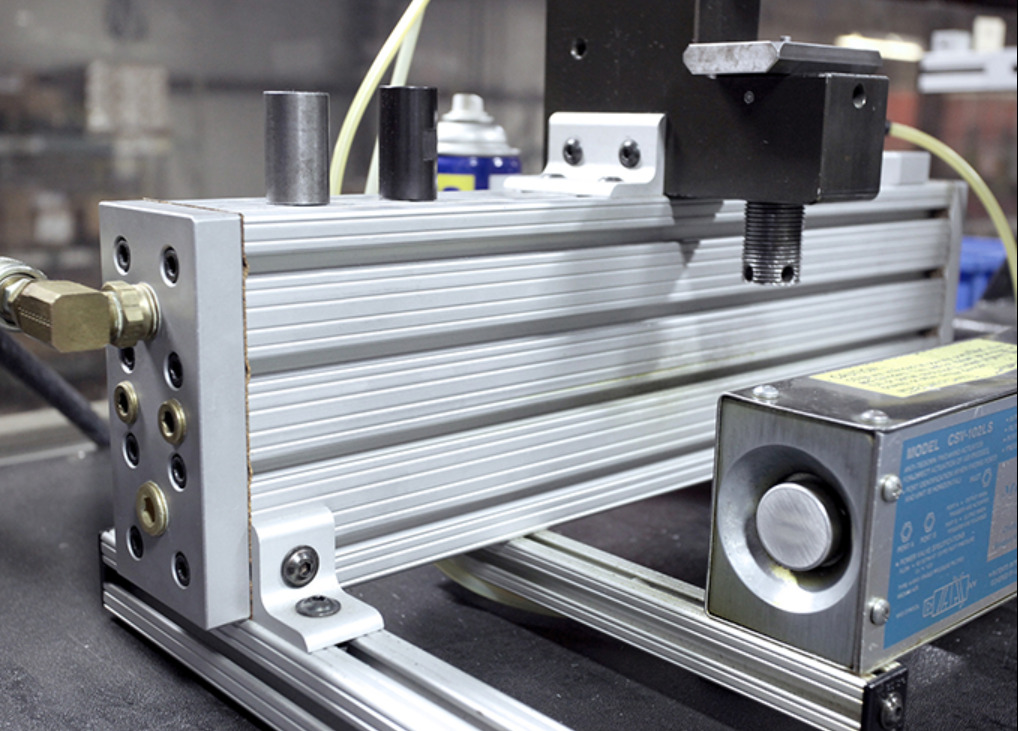

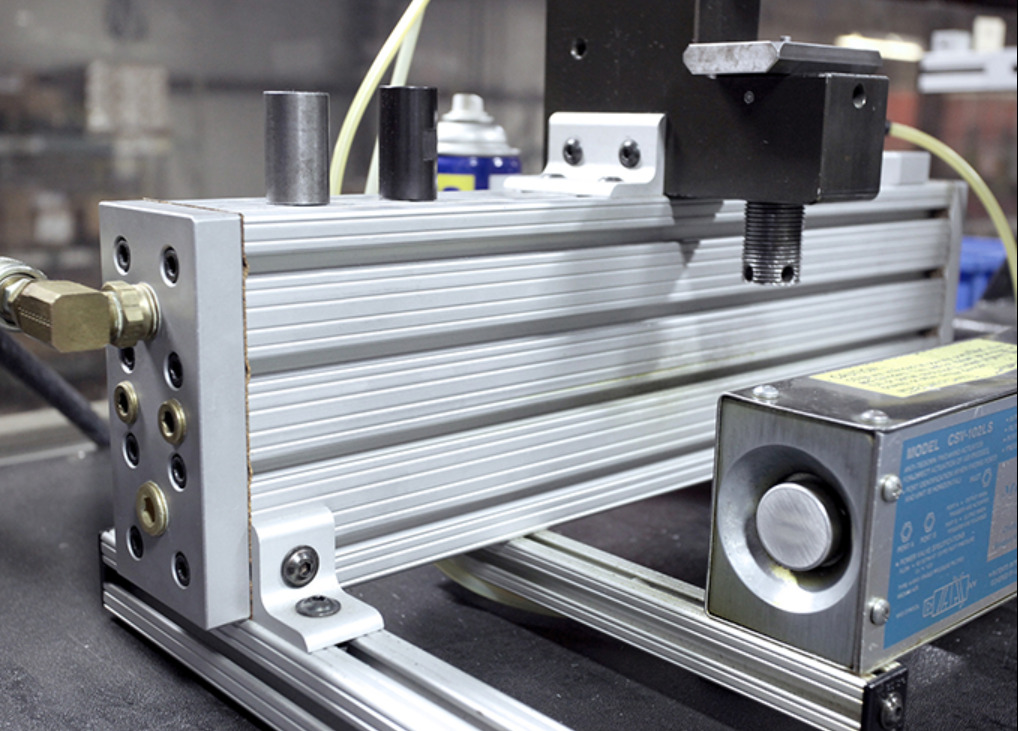

The 80/20 T-Slot aluminum building system takes modular framing to a whole new level, and is the perfect solution for light to heavy-duty applications.

This modular, lightweight, yet strong system offers endless configurations for professional and industrial applications.

Aluminum conducts heat and cold better than other common metals, making extrusion ideal for applications requiring heat exchangers or heat dissipation. Aluminum does not burn and even at extremely high temperatures does not produce toxic fumes.

While there are a variety of standard extrusion profiles available, the ability to design a profile to meet specific functional, aesthetic, and manufacturability objectives, makes aluminum extrusion a preferred choice.

Aluminum combines strength with flexibility and can flex under loads and spring back from the shock of an impact. This is why extruded components are perfect for automotive crash management systems.

Due to its clear anodized coating for increased corrosion and wear resistance, aluminum does not rust.

Aluminum is recyclable, with no degradation in properties. Aluminum extrusion is often created with a high recycled content, without compromising aesthetics or functionality. It is about 1/3 the weight of steel, iron, brass, and copper.

Aluminum is an excellent conductor of both heat and cold, making it ideal for a variety of industrial applications. Its low density also makes aluminum an excellent conductor of electricity.

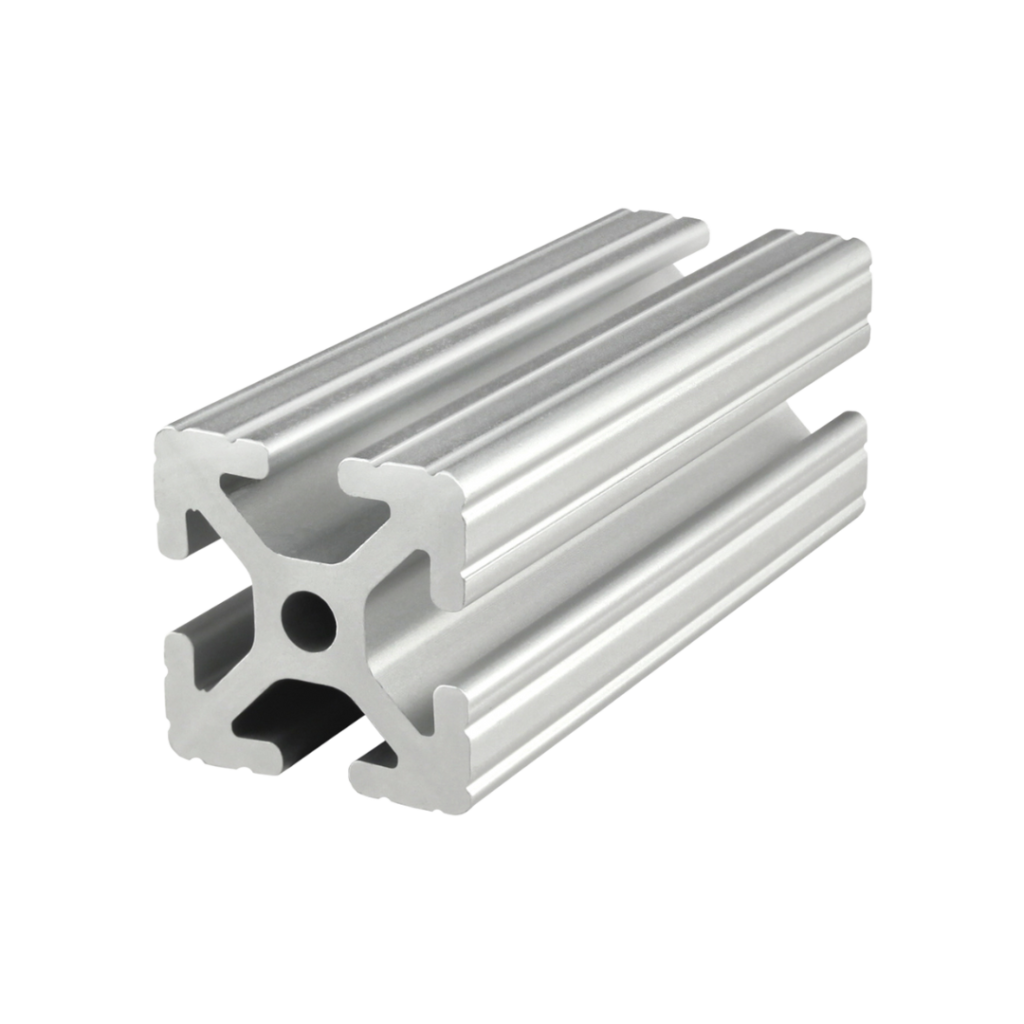

1515 is a 1.50” x 1.50” fractional 15 series square T-slot profile with four open T-slots, one on each 1.50” face. The profile has align-a-grooves to assist in alignment when connecting profiles. The 1515 profile is compatible with all 15 series fasteners. This profile is the most heavy-duty in the 1515 profile family and lends itself to clean room applications, guards, enclosures, or desks.

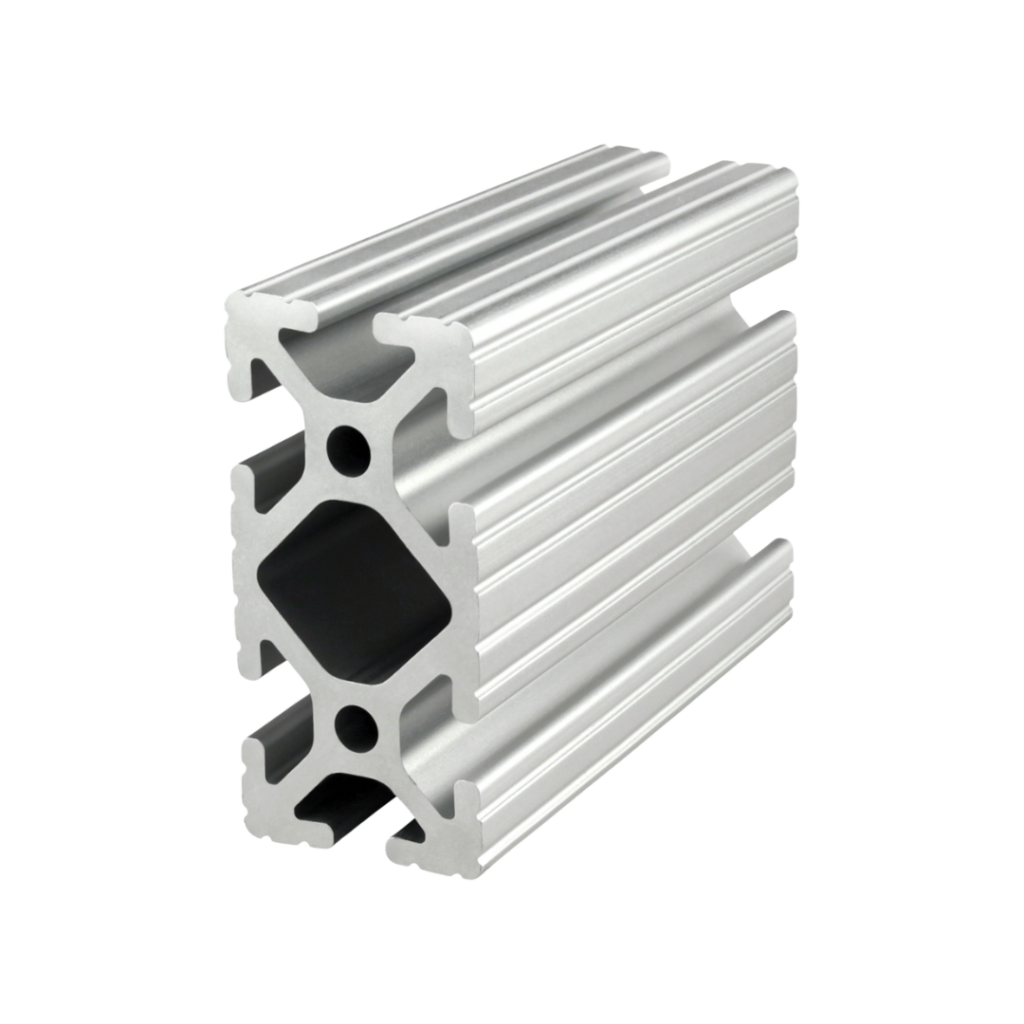

1530 is a 1.50” x 3.00” fractional 15 series rectangular T-slot profile with six open T-slots, two on each 3.00” face and one on each 1.50” face. The profile has align-a-grooves to assist in alignment when connecting profiles. The 1530 profile is compatible with 15 series fasteners. The center cavity of the profile can be pressurized up to 150 psi, lending itself to work spaces, machine guards, displays and panel mount racks.

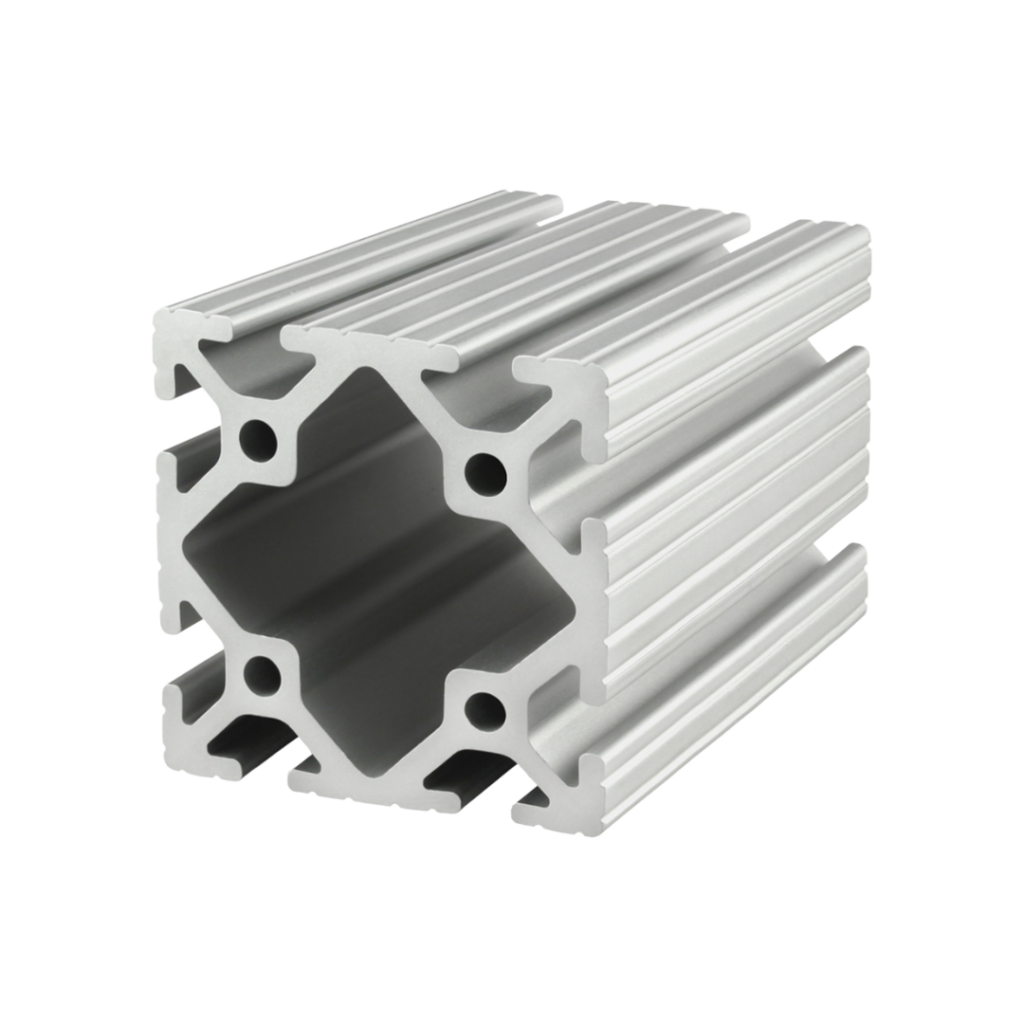

3030 is a 3.00” x 3.00” fractional 15 series square T-slot profile with eight open T-slots, two on each 3.00” face. The profile has align-a-grooves to assist in alignment when connecting profiles. The 3030 profile is compatible with 15 series fasteners and has a center cavity that can be pressurized up to 150 psi. The eight open T-slots, strength, and ability to pressurize this profile make it a great choice for automation applications, machine frames and workstations.

1530 is a 1.50” x 3.00” fractional 15 series rectangular T-slot profile with six open T-slots, two on each 3.00” face and one on each 1.50” face. The profile has align-a-grooves to assist in alignment when connecting profiles. The 1530 profile is compatible with 15 series fasteners. The center cavity of the profile can be pressurized up to 150 psi, lending itself to work spaces, machine guards, displays and panel mount racks.

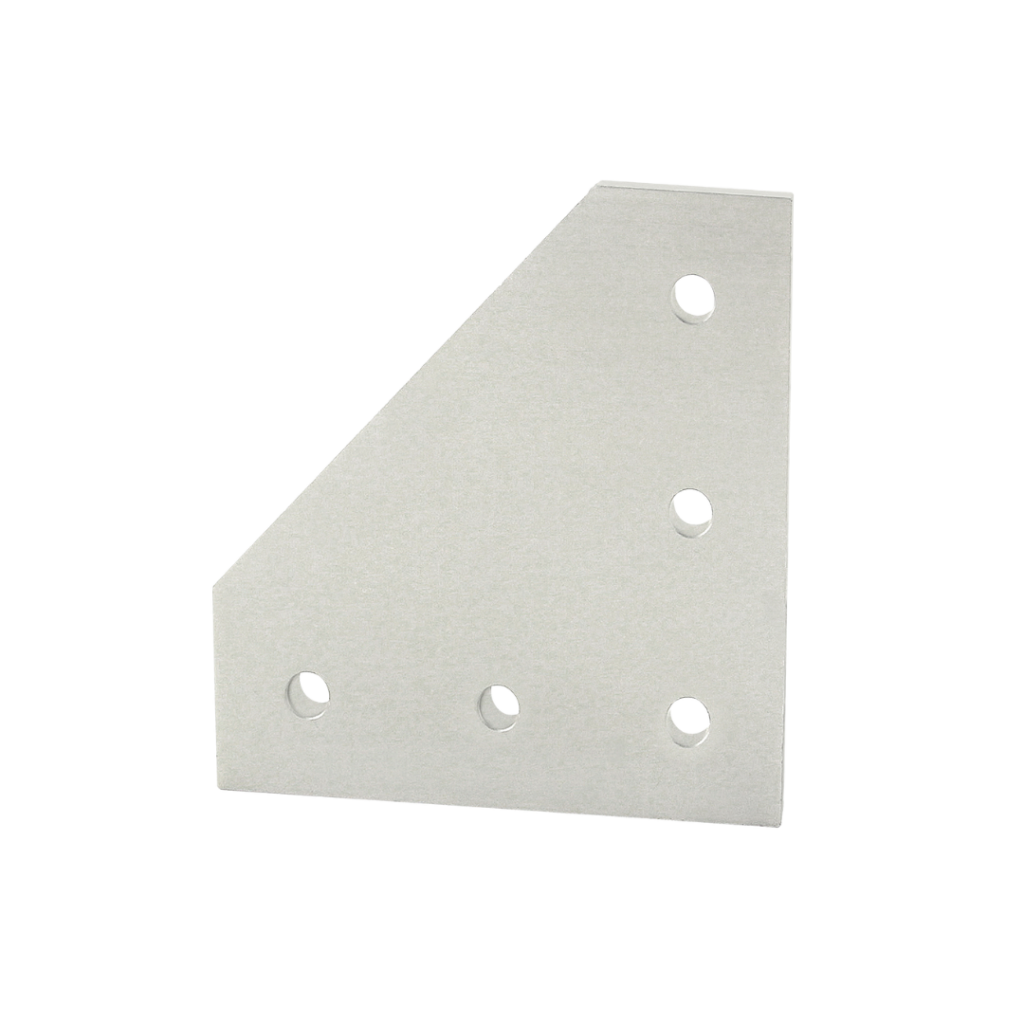

The 5 hole – 90 degree angled flat plate is an external fastening method that requires no machining services. This flat plate creates a 90-degree angle between profiles and its shape reinforces the strength of the connection. It is a durable option that is easy to assemble and can be reconfigured and reused. The suggested mounting hardware can be found on the “Suggested Hardware” tab. Tip: Use double or triple slide-in economy T-nuts to save time and money. Pre-load your hardware prior to connecting profiles to simplify your assembly.

3320 is comprised of…

80/20 provides T-slot aluminum profiles, or bars, that have channels used to connect other bars and parts — such as panels, linear bearings or casters. It is a building system anyone can use to create custom solutions.

One of the many benefits you’ll find with 80/20 profiles and parts is its versatility. From machine guards to robot arms to racing simulators to workstations – 80/20 is the answer.

Aluminum combines strength with flexibility and can flex under loads, or spring back from the shock of impact, which is why extruded components are used in automotive crash management systems. Contact us to see if aluminum extrusion is right for your weight load.

With its modular design, all you need are simple hand tools — no welding required.

T-slot profiles are strong and modular, and adjustments and assembly are straightforward and fast.

From planning and design to fabrication and installation, our team of engineering specialists help create a customized solution designed to meet your extrusion requirements.

The 80/20 T-Slot aluminum building system takes modular framing to a whole new level, and is the perfect solution for light to heavy-duty applications.

This modular, lightweight, yet strong system offers endless configurations for professional and industrial applications.

Aluminum conducts heat and cold better than other common metals, making extrusion ideal for applications requiring heat exchangers or heat dissipation. Aluminum does not burn and even at extremely high temperatures does not produce toxic fumes.

While there are a variety of standard extrusion profiles available, the ability to design a profile to meet specific functional, aesthetic, and manufacturability objectives, makes aluminum extrusion a preferred choice.

Aluminum combines strength with flexibility and can flex under loads and spring back from the shock of an impact. This is why extruded components are perfect for automotive crash management systems.

Due to its clear anodized coating for increased corrosion and wear resistance, aluminum does not rust.

Aluminum is recyclable, with no degradation in properties. Aluminum extrusion is often created with a high recycled content, without compromising aesthetics or functionality. It is about 1/3 the weight of steel, iron, brass, and copper.

Aluminum is an excellent conductor of both heat and cold, making it ideal for a variety of industrial applications. Its low density also makes aluminum an excellent conductor of electricity.

80/20 provides T-slot aluminum profiles, or bars, that have channels used to connect other bars and parts — such as panels, linear bearings or casters. It is a building system anyone can use to create custom solutions.

One of the many benefits you’ll find with 80/20 profiles and parts is its versatility. From machine guards to robot arms to racing simulators to workstations – 80/20 is the answer.

Aluminum combines strength with flexibility and can flex under loads, or spring back from the shock of impact, which is why extruded components are used in automotive crash management systems. Contact us to see if aluminum extrusion is right for your weight load.

With its modular design, all you need are simple hand tools — no welding required. T-slot profiles are strong and modular, and adjustments and assembly are straightforward and fast.

Aluminum Extrusion

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/