Leverage the latest enhancements in robotics

Robotics

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

Robotic integration utilizes robots in strategic areas to automate those dirty, deadly & dull tasks. Our team of Automation Engineers and Product Specialists audit facilities, material handling, shipping, and manufacturing lines to identify inefficient processes. The next step is to design and implement our innovative robotic technology, whether industrial or collaborative.

Industrial robotic systems are designed to perform repetitive actions in the following industrial settings:

Collaborative robots — also known as cobots — work alongside employees to efficiently perform tasks. Cobots vary greatly in size and are designed to handle a wide variety of tasks. They are easy to set-up and program, and safe to operate.

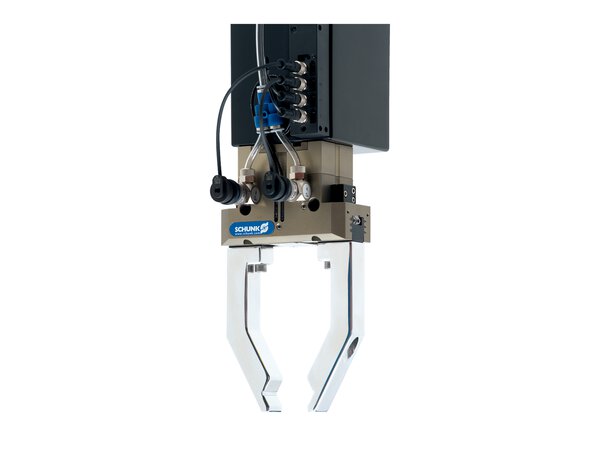

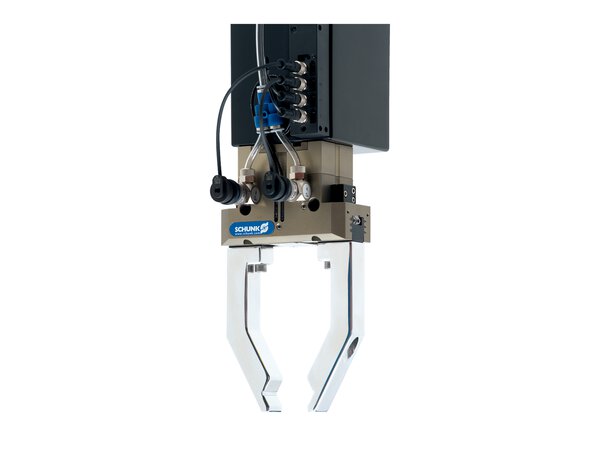

Valley Fluid Components is proud to partner with Schunk and offer robotic accessories such as gripping systems and tool & workpiece clamping technology.

3-Jaw Concentric Grippers

Area Scanners

Automated Material Transport

Assembly and Integration

Case Packing Robots

Collaborative Robots

Custom Robotic Arm Ends

Grippers

Light Curtains

Material Handling Robots

Painting Packages

Palletizing Robots

Parallel Axis Robots

Pick and Place Robots

Safety Mats

System Design

Tool Changers

Turnkey Machine Tending

Turnkey Parts Feeding Systems

Press Automation

Robotic Benching

GoFa is the perfect collaborative robot with class-leading reach, payload capacity up to 5kg, advanced and comprehensive safety, and easy operation.

VFC is proud to have ABB’s GoFa CRB 15000 currently in inventory and ready to purchase.

As the No. 1 universal gripper, it is the most proven and versatile gripper on the market.

*Compared to a T-slot guidance

Robotic integration utilizes robots in strategic areas to automate those dirty, deadly & dull tasks. Our team of automation engineers and product specialists audit facilities, material handling, shipping, and manufacturing lines to identify inefficient processes. The next step is to design and implement our innovative robotic technology, whether industrial or collaborative.

Industrial robotic systems are designed to perform repetitive actions in the following industrial settings:

Collaborative robots — also known as cobots — work alongside employees to efficiently perform tasks. Cobots vary greatly in size and are designed to handle a wide variety of tasks. They are easy to set-up and program, and safe to operate.

Valley Fluid Components is proud to partner with Schunk and offer robotic accessories such as gripping systems and tool & workpiece clamping technology.

3-Jaw Concentric Grippers

Area Scanners

Automated Material Transport

Assembly and Integration

Case Packing Robots

Collaborative Robots

Custom Robotic Arm Ends

Grippers

Light Curtains

Material Handling Robots

Painting Packages

Palletizing Robots

Parallel Axis Robots

Pick and Place Robots

Safety Mats

System Design

Tool Changers

Turnkey Machine Tending

Turnkey Parts Feeding Systems

Press Automation

Robotic Benching

GoFa is the perfect collaborative robot with class-leading reach, payload capacity up to 5kg, advanced and comprehensive safety, and easy operation.

As the No. 1 universal gripper, it is the most proven and versatile gripper on the market.

*Compared to a T-slot guidance

Robotics

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

Robots work hand-in-hand with Material Handling & Industrial Conveyors and are designed to handle all stages of the manufacturing process, from production and assembly to inspection and packing.

Keeping people and equipment safe is critical, which is why 80/20 provides a wide variety of aluminum extrusion products to safely house your robotic systems.