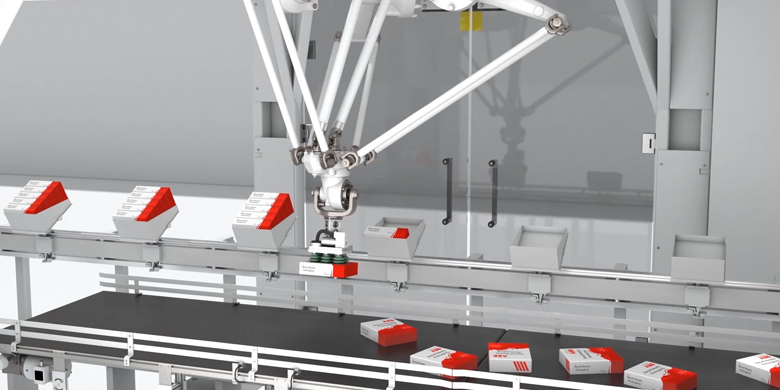

The IRB 390 FlexPacker is a ground-breaking innovation in Delta Robot technology. IRB 390 FlexPacker delta robot is designed for rapid changeover times that accompany the growth of low volume, high mix production to respond to the revolution of new consumer demands. It addresses the rising demand for Shelf Ready- (SRP) and Retail Ready packaging (RRP) by promoting shelf presence, enabling higher payload and flexibility while maintaining speed.

5 axes capability increases application flexibility for Shelf Ready Packaging, parcel sorting, and bottle unscrambling.

The variant with a 5th axis (10 kg) offers greater dexterity and flexibility than equivalent 4-axis (15 kg) robots, including the ability to vertically orient boxes and parcels, while achieving higher speeds than 6-axis units.

35% faster and 45% larger working volume*. Working seamlessly with ABB’s IRB 360 FlexPickerTM and PickMaster® Twin, ABB’s market leading robotic software for vision-guided random flow picking and packing applications, allowing the building of simulated packing stations to optimize the picking process.

With its class leading cycle time performance, the IRB 390 can pick products from high-speed systems running at up to 100 m/min and place them into cases, trays, crates or other packaging formats.

Food & Beverage

With the ability to handle multipacks and vertically orient products such as juice cartons, the IRB 390 is ideal for food and beverage picking and packing applications. Objects can be selected from lines running at up to 100 meters per minute and place them into cases, trays, crates or other packaging mediums. The use of food grade lubricants and FDA compliant materials enable the IRB 390 to be used where there is proximity to open products.

Logistics

Able to quickly sort, pick and place parcels, boxes and cartons of varying sizes, shapes and weights up to 15kg, the IRB 390 enables a wide variety of goods to be picked, packed and made ready for delivery in the shortest possible time. Its speed and flexibility offer a highly effective solution to meet the challenges of omnichannel retailing where goods need to be delivered in a variety of ways to a variety of customer types.

Pharmaceutical

Built to meet FDA standards for use in hygienic environments, the IRB 390 can be used to sort, pick and pack a range of pharmaceutical products. With the ability to handle multiple products, it can pack complete layers into narrow cartons increasing quality and throughput and improving productivity.

Consumer Packaged Goods

The IRB 390’s combination of speed, flexibility and high payload capability makes it ideal for handling a full range of goods, including clothing, cosmetics and personal care, cleaning products and household products. With its enhanced throughput, the IRB 390 can help to reduce the time needed to pick, pack and despatch orders to customers, from retailers through to individuals.

Robotics Product Range brochure robots -robot selection table, (PDF 16 pages) 2023IRB 760 Datasheet

Summary: new robots including IRB 1090, IRB 6710, IRB 6720, IRB 6730, IRB 6740, IRB 930.

IRB 390, IRC5, Product specification

Summary: IRB 390, IRC5/M2004, Product specification

Ready to up your production game with ABB’s IRB 390 FlexPacker®? Valley Fluid’s sister brand, PennAir, is here to be your trusted partner. Whether you’re looking to enhance your automation capabilities or troubleshoot any issues, their team is fully equipped and ready to assist you.

Connect with us

Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.