For more than 100 years SCHNEEBERGER has set the benchmark for ultra‑precise linear motion. From Swiss‑engineered guideways first introduced in 1923 to today’s fully integrated measuring and drive systems, the company focuses on one thing: flawless, repeatable movement. Whether you’re building machine tools, semiconductor equipment, medical devices, or heavy‑duty automation, SCHNEEBERGER solutions boost throughput, raise positional accuracy, and slash maintenance costs.

Engineered completely to your needs – width, length, hole pattern, and even coating. Low‑friction sliding surfaces are ground after coating for perfectly smooth motion, optional lubrication grooves extend service intervals, and integration is quick because the parts arrive ready to install. Ideal where recirculating balls won’t fit or shock loads are extreme.

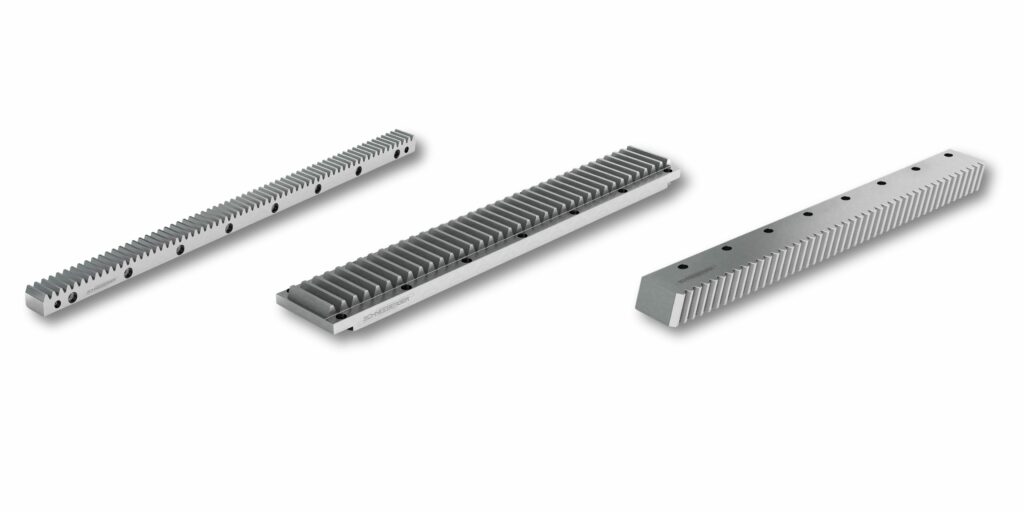

Hardened, precision‑ground racks convert rotary power to linear travel over virtually unlimited lengths. Tight pitch accuracy (<20 µm/500 mm) and finely finished flanks deliver whisper‑quiet, backlash‑free motion in high‑speed gantries, press feeds, and large‑format CNC machines. CAD files, paired pinions, and custom lengths come standard.

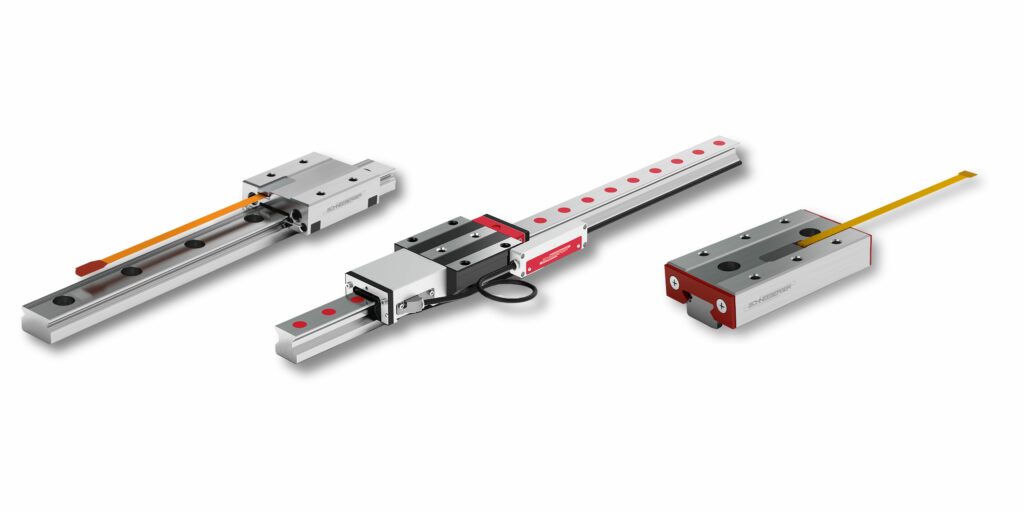

MONORAIL AMS and MINISCALE PLUS combine a high stiffness guideway and an absolute or incremental encoder strip in one compact rail, delivering sub-micron positioning feedback, simplified mounting, and reduced machine build time while keeping the measuring scale protected from contaminants.

Ultra‑High Precision

Sub‑micron straightness & flatness tolerances on every rail

Optional integrated measuring scales deliver closed‑loop accuracy to ±1 µm

ISO‑certified test reports supplied with each shipment

Engineering Freedom

Mix‑and‑match portfolio: miniature rails, roller guideways, gear racks, linear tables

Fast customization: hole patterns, coatings, preload, specialty materials

In‑house application engineers co‑design for load, speed & environment

Free CAD models and life‑calculation tools accelerate machine design

Productivity for Life

Hardened raceways plus OPTIcoat® options cut wear and extend service intervals

Integrated lubrication ports slash downtime and maintenance labor

Global spare‑parts & field‑service network keep lines running 24/7

Proven reliability: MTBF > 100 million cycles in heavy‑duty automation and CNC machines

MONORAIL and AMS Application

Application guide with design, installation, lubrication, and maintenance advice for MONORAIL and AMS systems.

Linear Bearings and Recirculating Units

Manual summarizing linear guideways and recirculating units plus load, life, and installation calculations.

Ready to boost your machine accuracy with SCHNEEBERGER guideways, gear racks, and integrated measuring systems? VFC’s sister brand, PennAir, is your trusted local partner. Their Pennsylvania-based team can help you select, install, and service SCHNEEBERGER products to keep your lines running at peak precision.

Connect with us

Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.