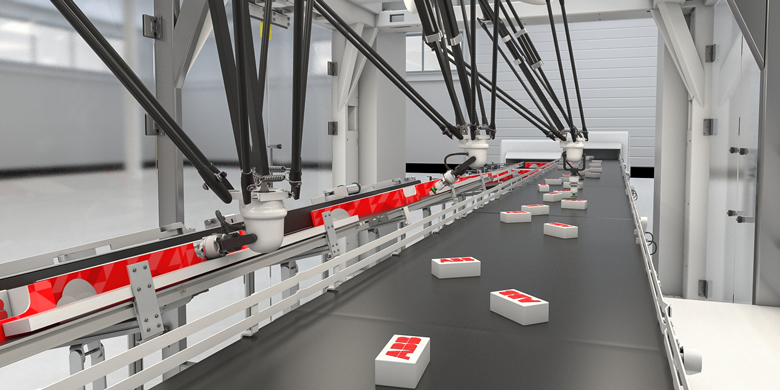

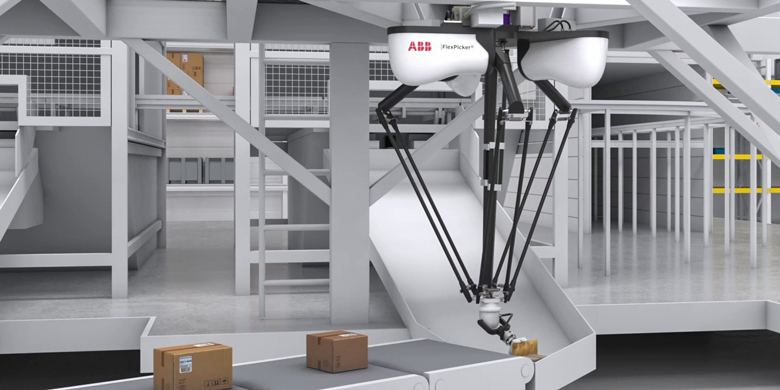

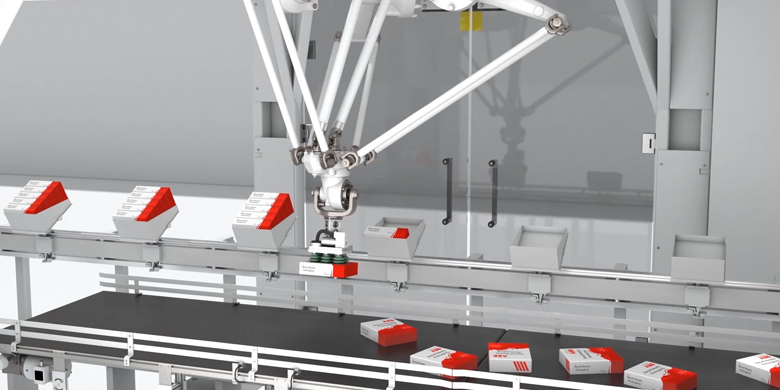

With the same five axes and 1.5kg payload, the three variants (800mm, 1100mm, 1300mm) of IRB 365 FlexPicker® Delta robot are flexible and the fastest in their class for reorientating packaged lightweight products such as cookies, chocolates, peppers, candies, small bottles, and parcels.

5 axes capability increases application flexibility for Shelf Ready Packaging, parcel sorting, and bottle unscrambling.

Pick reorientate and place 1kg products at 120 picks per minute*, the fastest in the class.

PickMaster® Digital Twin reduces commissioning times from days to hour and changeover times from hours to minutes.

Offers best-in-class motion control, built-in digital connectivity, and 1000+ additional functions.

Secondary packaging

Top loading, Shelf Ready Packaging (SRP), and by tilting products in packaging.

Bottle handling and unscrambling

Picking random orientation bottles laying flat and standing them up.

3D picking

Identifying product characteristics and place to an orientation.

Feeding

Picking from a random flow and placing vertical.

On edge placing

Picking products and placing on edge

Parcel sorting

Singulation of random bulk parcels and parcel orientation.

Food & Beverage

Logistics

Pharmceutical

Consumer Packaged Goods

Product specification – Robot stopping distances according to ISO 10218-1 390, IRC5, Product specification

Summary: This specification contains stopping distances and times for category 0 and category 1 stops, as required by EN ISO 10218-1 Annex B. This specification should be used when calculating the safe distance in applying safeguarding devices.

IRB 365, OmniCore, Product specification

Summary: IRB 365, OmniCore, Product specification

Ready to up your production game with ABB’s IRB 365 FlexPicker®? Valley Fluid’s sister brand, PennAir, is here to be your trusted partner. Whether you’re looking to enhance your automation capabilities or troubleshoot any issues, their team is fully equipped and ready to assist you.